LEONARD. The tyre makes its revolution.

THE circular revolution !

>> Read more

To completely rethink the way we produce, sell and use tyres.

To convert a linear activity that did not close the loop to the circular economy.

To reuse materials from thousands of used tyres.

To reinvest in France an industrial know-how that has long been disregarded: tyre retread?

To offer everyone, professionals, professional clients and individuals, a reliable and proven alternative.

So yes, Leonard is revolutionizing the tyre, to make it always possible to circulate freely.

To go to school, to work on vacation, wherever you want! For a long time.

For today and for tomorrow.

WHAT IS THE LEONARD TYRE ?

The Leonard tyre is :

- a large-scale remanufactured tyre for the general public (passenger vehicles and utility vehicles)

- a tyre manufactured using a reconditioning / remanufacturing process that guarantees high standards of quality and performance.

- a tyre that promotes reuse: reuse of material, of an industrial site and of local know-how.

By purchasing Leonard tyres, you are purchasing products that have been produced locally with reused materials and you are contributing to the life of a region and its industry.

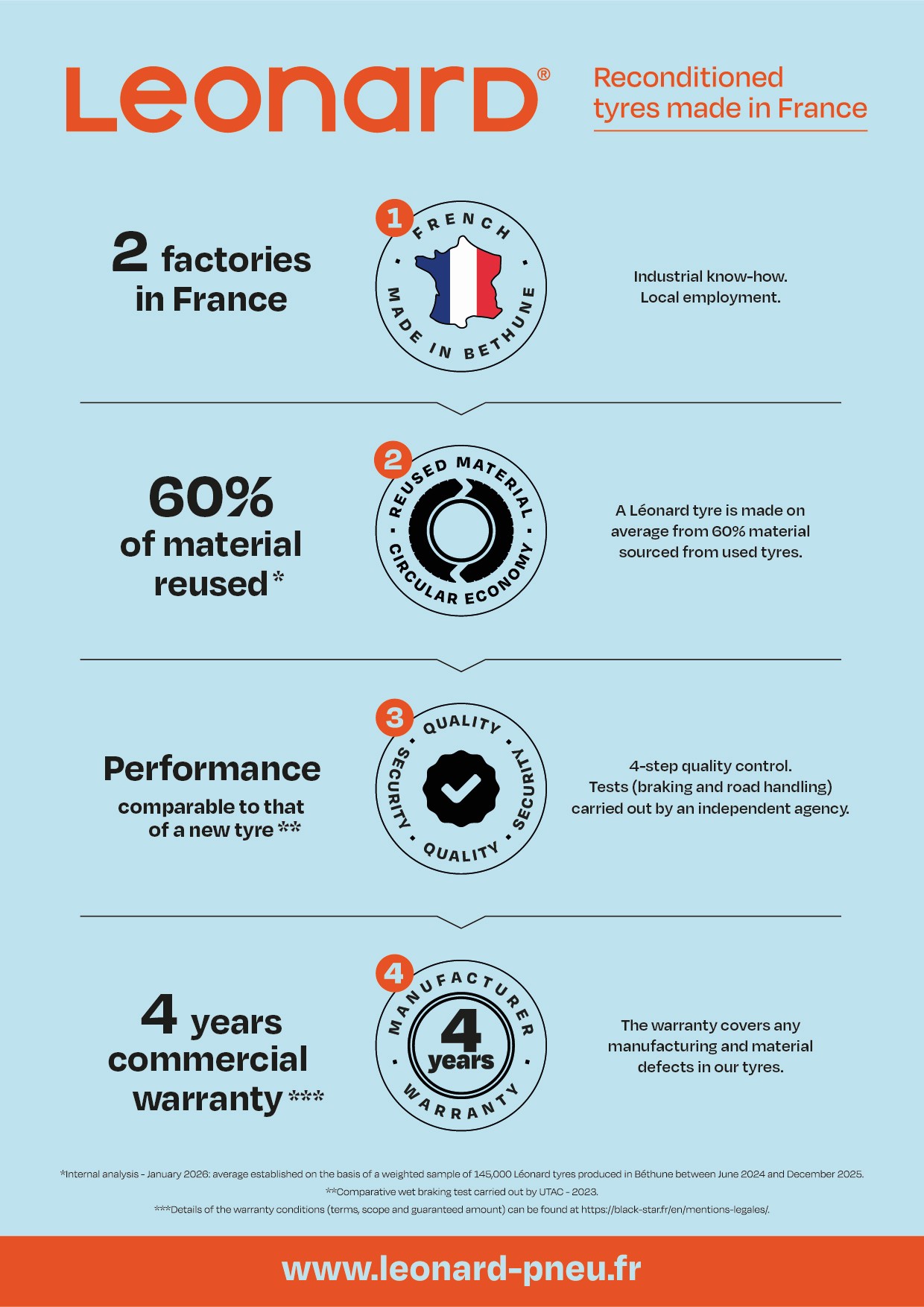

The 4 pillars of the LEONARD tyre

1. French

2 remanufacturing plants in France

Industrial know-how

Local employment

2. Material reuse

60% of material reused on average

(Internal study January 2026 – based on a weighted sample of tyres produced in Béthune)

3. Quality and Security

Thanks to a premium industrial tool.

Quality control in 4 steps

Performance comparable to that of a new tyre (UTAC 2023 comparative test test)

4. 4 year warranty

4-year commercial warranty

The warranty covers any manufacturing and material defects in our tyres.

The French tyre "Made in Béthune"

Black Star has decided to deploy, in Béthune, an integrated ecosystem serving the second life of tyres, on the industrial site of the former manufacturer Bridgestone.

Thus, it benefits from a valuable business opportunity, relying on the enthusiasm of men and women who know the trade, the site, and the equipment. These are invaluable advantages for producing a quality remanufactured tyre.

Leonard is a tyre serving a cause that contributes to:

- Reindustrialization of an industrial site in Hauts-de-France.

- Revitalizing the employment area: generating sustainable and non-relocatable local employment, employment compatible with the skills of former Bridgestone employees, recruitment method by simulation.

Reused material

Leonard tyres are made from recycled material.

On average, 60% of each Leonard tyre comes from used tyres (Internal analysis – January 2026: average established on the basis of a weighted sample of 145,000 Leonard tyres produced in Béthune between June 2024 and December 2025).

This represents approximately 5.75 kg of reused material per tyre, which is equivalent to the amount of raw materials saved.

The parts of the tyre casing that are not reused are entirely transformed into powder for other uses by a specialized service provider. The used tyre is thus fully recovered (100%).

Unlike a new tyre, a reconditioned tyre converts waste into a resource, thus fitting into a circular economy model.

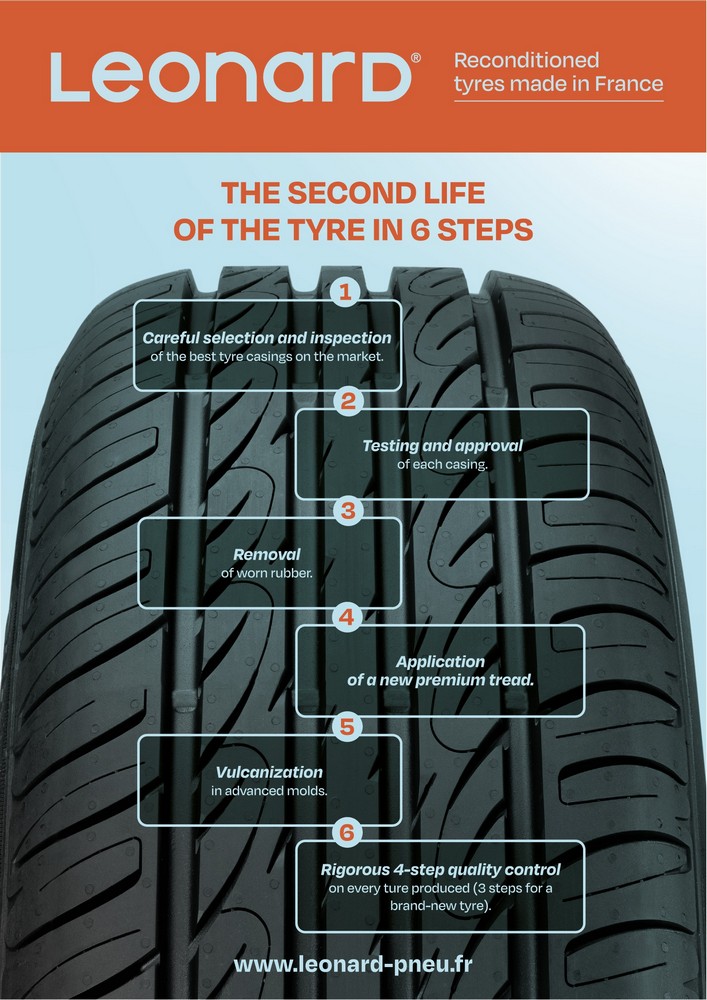

Performance comparable to that of the new tyre

Subject to specific European regulations, but very similar to a new tyre, quality and safety remain the glue in the design of the Leonard tyre. Their manufacture complies with UNECE Regulation No. 108 establishing uniform requirements for the approval of the manufacture of retreaded tires for motor vehicles and UNECE Regulation No. 109 establishing uniform requirements for the approval of the manufacture of tires retreaded for utility vehicles and their trailers.

In Béthune, we have inherited know-how and premium industrial tools (equivalent to that of a new major brand tyre).

The rubber compounds are exclusive and developed in conjunction with a new tyre manufacturer. Their extrusion respects precise dimensions to ensure perfect regularity of the tyre circumference. A bonding sheet based on natural rubber, without synthetic rubber, allows the new material to achieve a tear resistance that is 30 to 80% higher than the orbitread process, as demonstrated by internal comparative tests and those carried out at the LRCCP.

Before being marketed, 100% of finished products must undergo a 4-step quality control process (visual inspection, unbalance inspection, uniformity inspection and shearography inspection), one more step than for a new tyre.

Leonard tyres are subject to load/speed endurance tests approved by the UTAC organization. The endurance tests required are strictly identical to those carried out on new tyres.

Below are the results of the measurements of the Leonard tyres (205/55R16 91V) in comparison with premium brand and budget brand tyres (European production) made by UTAC (2023) on the Mortefontaine track.

Obstacle avoidance Test

(VDA)

| LEONARD | 68,0 Km/h | 101,50% |

| PREMIUM | 67,0 Km/h | 100,00% |

| BUDGET (EU) | 67,0 Km/h | 100,00% |

Wet braking

(80Km/h → 0Km/h)

| PREMIUM | 32,55 m | 100,00% |

| LEONARD | 32,66 m | 99,60% |

| BUDGET (EU) | 33,79 m | 96,90% |

Dry braking

(100Km/h → 0Km/h)

| PREMIUM | 40,67 m | 100,00% |

| BUDGET (EU) | 41,90 m | 97,10% |

| LEONARD | 43,16 m | 93,80% |

Quality guaranteed for 4 years

We are so confident in the quality of our tyres that we offer a 4-year warranty. The warranty covers any manufacturing and material defects in our tyres (see details of the terms and conditions of this warranty at: www.black-star.fr/en/mentions-legales).

A complete range

The Leonard tyre is a quality reconditioned tyre for passenger and utility vehicles.

It is made from recycled materials (used tyre casings). It offers good grip and optimal safety, and guarantees a low level of rolling resistance.

The Leonard tyre is available in 4 different profiles: 4 Seasons for passenger cars and SUVs, 4 seasons for utility vehicles and two summer profiles (Summer 01 and 02) for passenger cars.

The 4 summer profiles are designed for dynamic and safe driving with excellent handling and maximum grip. The 4-season tyre offers a perfect combination of performance on dry and wet roads as well as on snow and ice. It also has excellent resistance to aquaplaning. LEONARD 4-season reconditioned tyres (passenger and utility) fall under the “3PMSF” (3 Peak Mountain Snow Flake) designation in compliance with the Mountain Law from November 1 to March 31, in certain mountainous areas.

The Leonard tyre is available in a wide range of sizes and pressures.

Summer profile for passenger cars

4 Seasons for passenger cars and SUVs

4 seasons for utility vehicles